The worldwide corrosion inhibitors market is predicted to expand from 5100 kilo tons in year 2015 at a CAGR growth rate of greater than 4% till end of year 2023 in terms of output. The global industry is forecasted to cross 8800 million US dollars by end of year 2023 in terms of revenue.

Growing use of the corrosion inhibitors in water treatment, refining and energy production are predicted to promote the demand and growth of the worldwide corrosion inhibitors market. Further, increasing application of corrosion inhibitors for different iron & steel devices that are basically utilized in mining & construction sector is anticipated to contribute towards the demand & expansion of the worldwide industry. Technological breakthroughs and continuous product innovation resulting in growing application of green inhibitors and nanotechnology in corrosion inhibitors is predicted to generate new avenues for the market growth in future.

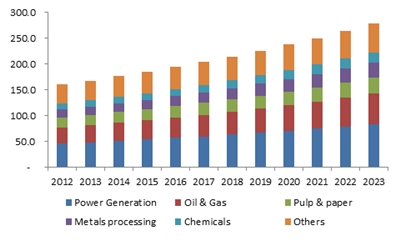

MEA corrosion inhibitors market size, by end-use, (USD Million) 2012-2023

But many ecological issues related with raw substances utilized in corrosion inhibitors can hinder the growth & expansion of the worldwide corrosion inhibitors market. Deadly effects of these conventional inhibitors on marine life, human beings and plants along with problems regarding its disposal can also inhibit the development & expansion of the industry in future.

Based on the product, the worldwide corrosion inhibitors market is bifurcated into inorganic inhibitors and organic inhibitors.

Organic inhibitors section was the biggest product section contributing largest share to the total share of the worldwide corrosion inhibitors market during year 2015. The growth of this section can be attributed to the nonexistence of metals in organic inhibitors leading to prevention of unnecessary reactions. Further, growing application of organic inhibitors in construction segment and oil & gas segment is predicted to stimulate the demand for organic inhibitors. This section is predicted to be rapidly evolving section during the estimated span owing to increasing choice of customers.

Growing use of inorganic inhibitors in water treatment application due to its enhanced functions over array of temperatures and different levels of pH will propel the demand of this product section during the estimated span. Implementation of environment friendly rules on inorganic inhibitors in countries like UK, USA and Germany are predicted to boost the sale and demand of these inhibitors in future.

Depending upon the applications, the worldwide corrosion inhibitors market is divided into solvent based corrosion inhibitor and water based corrosion inhibitor.

Water based corrosion inhibitor section led the worldwide corrosion inhibitors market during years 2012 and 2015. Growing consciousness about the adverse impacts of volatile organic compounds emissions on human beings along with negligible VOC emissions from this section is predicted to stimulate the demand & growth of the section in future.

Further, the rising demand for the application in high temperature applications like oil extraction and refining is predicted to be yet another aspect adding towards the growth of the global industry. Also these inhibitors are inexpensive, become transparent after drying and are applied by using different procedures like immersion, brush or spray. All these factors drive the growth & demand of this section.

The solvent based corrosion inhibitor section is predicted to experience slow growth owing to its limited scope of application, high flammability and security risks. These inhibitors are utilised in applications requiring consistent performance over enlarged period and constant thickness of film that offers uniform security. They are utilised in electronics and automobile applications. The consistent performance of this section over a long span is predicted to stimulate its demand during estimated period.

Based on the end users, the global corrosion inhibitors market is segmented into pulp & paper, power generation, chemical processing, oil & gas and metal processing.

Power generation section led the worldwide corrosion inhibitors market during years 2012 and 2015 in terms of size. Increasing capital investments made by government on energy generation projects to fulfil the growing power requirements is predicted to stimulate the demand. In addition to this, energy production by using renewable energy sources like hydro power, wind energy and solar energy is predicted to act as a main aspect for market growth.

Oil & gas section was the second biggest end user section of global corrosion inhibitors market during year 2012. It is predicted to be the rapidly expanding section owing to growing demand of product in oil & gas pipelines helping in minimizing losses occurring at the time of refinement procedures. Further, the existence of tremendous proportion of shale gas reserves in USA that can be recovered technically is predicted to fuel the growth of the industry during the estimated span. In addition this, increase in industrial events all across the emerging nations as well as developed nations is projected to stimulate the demand & growth of the oil & gas section. This in turn is forecasted to enhance the development of corrosion inhibitors market worldwide.

Depending upon the geographical locations, the worldwide corrosion inhibitors market is segmented into four geographical regions, namely, North American subcontinent, Europe, APAC zone and region of the rest of world.

The APAC zone contributed to biggest share to the total share of the worldwide corrosion inhibitors market in demand terms during year 2012. This zone also contributed highest share to the total share of global industry in terms of revenue during year 2015. Rapid industrial development, growth in construction sector and growing consciousness about the negative effects of corrosion are few of the factors contributing to the demand & growth of corrosion inhibitors market in APAC zone.

APAC zone is predicted to experience substantial growth due to urban & industrial growth in India and China. Further, product improvement and rising steel production along with expansion of oil& gas segment in countries like Australia, India and China of Asia Pacific zone will stimulate the demand for product in future. Also, growing expenditure on construction activities along with fast economic growth in countries like South Korea, China, Thailand, India and Indonesia is estimated to develop enormous market potential during the forecasted span.

Europe and North American subcontinent combined contributed towards more than half of the total share of the worldwide corrosion inhibitors market during year 2012.

The European continent was the second biggest market for corrosion inhibitors. Increase in power generation in countries like UK and Germany and rise in proportion of nuclear plants in countries like Sweden, UK and Poland are expected to open new market growth avenues for corrosion inhibitors in Europe in future. But strict environmental rules on discharging of toxic wastes in the chemical form can hinder the growth of corrosion inhibitors market during the forecasted period.

Further, industrial growth in the nations like South Africa and Brazil has resulted in increase of construction events. This is predicted to add towards substantial growth of worldwide corrosion inhibitors market during forecasted period.

Request sample research report: https://www.gminsights.com/request-sample/detail/389

The worldwide corrosion inhibitors market features new product development and constant research & development by key industry participants to enhance the performance of their product offerings.

The key industry participants involved in this business and contributing towards the growth of the global corrosion inhibitors market are as follows:

• Nalco Company

• Ecolab Incorporation

• Cortec Corporation

• BASF Corporation/SE

• GE Water & Process Technologies

• Ashland Incorporation

• DuPont

• Milacron- Cimcool

• Kurita Water Industries Limited

• Henkel AG & Corporation/Company

• Renewable Lubricants Incorporation

• AkzoNobel N.V.

• Dow Chemical Company

• Champion Technology Services/Incorporation

• Cytec Industries Incorporation

• The Lubrizol Corporation

• United Corrosion Technologies

• NOF Metal Coating Group

• Anticorrosion Protective Systems LLC

• Air Products and Chemicals Incorporation

• Chemtreat Incorporation

• Dai Ichi Karkaria Limited

• Daubert Cromwell LLC

• Halox Incorporation

• QED Chemicals Limited

• Shawcor Limited

• Insituform Technologies Incorporation

• Kemira OYJ

• Mersen SA

• Rhodia

• Northern Technologies International Corporation NTIC

• Solutia Incorporation

• Dorf Ketal

• W.R. Grace & Corporation

• Marott Graphic Services

No comments:

Post a Comment